Page 146 - Peter Paul 2019 Catalog

P. 146

HAZARDOUS LOCATION HIGH PRESSURE VALVES

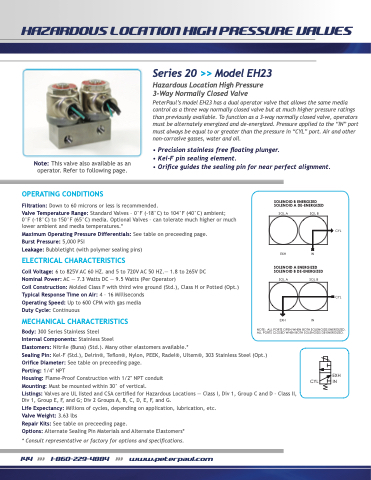

Series 20 >> Model EH23

Hazardous Location High Pressure

3-Way Normally Closed Valve

PeterPaul’s model EH23 has a dual operator valve that allows the same media control as a three way normally closed valve but at much higher pressure ratings than previously available. To function as a 3-way normally closed valve, operators must be alternately energized and de-energized. Pressure applied to the “IN” port must always be equal to or greater than the pressure in “CYL” port. Air and other non-corrosive gasses, water and oil.

• Precision stainless free floating plunger.

• Kel-F pin sealing element.

• Orifice guides the sealing pin for near perfect alignment.

Note: This valve also available as an operator. Refer to following page.

OPERATING CONDITIONS

Filtration: Down to 60 microns or less is recommended.

Valve Temperature Range: Standard Valves – 0°F (-18°C) to 104°F (40°C) ambient;

0°F (-18°C) to 150°F (65°C) media. Optional Valves – can tolerate much higher or much lower ambient and media temperatures.*

Maximum Operating Pressure Differentials: See table on preceeding page.

Burst Pressure: 5,000 PSI

Leakage: Bubbletight (with polymer sealing pins) ELECTRICAL CHARACTERISTICS

Coil Voltage: 6 to 825V AC 60 HZ. and 5 to 720V AC 50 HZ.— 1.8 to 265V DC

Nominal Power: AC — 7.3 Watts DC — 9.5 Watts (Per Operator)

Coil Construction: Molded Class F with third wire ground (Std.), Class H or Potted (Opt.) Typical Response Time on Air: 4 – 16 Milliseconds

Operating Speed: Up to 600 CPM with gas media

Duty Cycle: Continuous

MECHANICAL CHARACTERISTICS

SOLENOID B ENERGIZED

SOLENOID A DE-ENERGIZED SOLENOID B ENERGIZED

SOLENOID A DE-ENERGIZED SOSLOENL AOID B ENERGISZOEDL B

S O L E S N O O L I A D A D E - E N E R S GO L I Z B E D

SOL A

EXH

SOL B

IN

CYL CYL

CYL

CYL CYL

CYL

EXH EXH

SOSLOENLEONIODIDAAENENEREGRGIZIZEEDD SOSLOENLEONIODIDB BDED-EE-NENEERRGGIZIZEED

SOL A SOL B SOSLOENL OA ID A ENERGSIZOELDB

SOLENOID B DE-ENERGIZED

SOL A SOL B

IN IN

Body: 300 Series Stainless Steel

Internal Components: Stainless Steel

Elastomers: Nitrile (Buna) (Std.). Many other elastomers available.*

Sealing Pin: Kel-F (Std.), Delrin®, Teflon®, Nylon, PEEK, Radel®, Ultem®, 303 Stainless Steel (Opt.)

Orifice Diameter: See table on preceeding page.

Porting: 1/4′′ NPT

Housing: Flame-Proof Construction with 1/2′′ NPT conduit

Mounting: Must be mounted within 30° of vertical.

Listings: Valves are UL listed and CSA certified for Hazardous Locations — Class I, Div 1, Group C and D – Class II, Div 1, Group E, F, and G; Div 2 Groups A, B, C, D, E, F, and G.

Life Expectancy: Millions of cycles, depending on application, lubrication, etc.

Valve Weight: 3.63 lbs

Repair Kits: See table on preceeding page.

Options: Alternate Sealing Pin Materials and Alternate Elastomers*

* Consult representative or factory for options and specifications.

EXH EXH

IN IN

NOTE: ALL PORTS OPEN WHEN BOTH SOLENOIDS ENERGIZED.

ALL PORTS CLOSEEXDHWHEN BOTH SOLEINOIDS DE-ENERGIZED. NOTE: ALL PORTS OPEN WHEN BOTH SOLENOIDS ENERGIZED.

NOTE: ALL PORTS OPEN WHEN BOTH SOLENOIDS ENERGIZED. ALL PORTS CLOSED WHEN BOTH SOLENOIDS DE-ENERGIZED.

EXH CYL IN

ALL PORTS CLOSED WHEN BOTH SOLENOIDS DE-ENERGIZED.

144 >>> 1-860-229-4884 >>> www.peterpaul.com