Page 12 - Peter Paul 2019 Catalog

P. 12

VALVE CONFIGURATIONS

In addition to 2-way NO and 2-way NC closed, Peter Paul also offers two-position valves in other useful configurations. Many lend themselves to specific applications.

For example, a 3-way NC blocks compressed air from reaching a single- acting, spring-return pneumatic cylinder and vents the cylinder port to exhaust. Energizing the valve blocks the port to atmosphere and routes compressed air to the cylinder port. The valve’s exhaust port can simply be vented to atmosphere or to a common air exhaust line.

A 3-way NO valve routes compressed air to a pneumatic cylin- der and blocks the valve’s exhaust port. Energizing the valve blocks compressed air to the cylinder and opens the cylinder port to exhaust. Again, the valve’s exhaust port can simply be vented to atmosphere or to a common air exhaust line.

In a 3-way directional control valve, the supply port is open to the first of two outlet ports while the second outlet port is blocked. Shifting the valve routes flow to the second outlet port and blocks it to the first port.

A 3-way multi-purpose valve works like the directional control version, except that reverse flow can occur — inlet to outlet or outlet to inlet.

No matter what the configuration, the valve must be selected based on the cross-sectional area of its internal flow path — known as orifice size. For a given fluid at a given flow rate and temperature, the larger the orifice, the lower the pressure drop (ΔP) it will produce. So in addition to the type of valve and configuration, orifice size is an important specification that must be considered. Standard orifice sizes for Peter Paul valves run from 1/32 to 11⁄2 in.

SIZING AND SELECTION

Valves come in many standard port configurations but can be ordered with ports configured to an application. For example, ports can be placed in line with each other, parallel to each other, next to each other, or at right angles to each other.

They can also be ordered for use where fire or explosion hazards exist due to the presence of flammable gases or vapors, flammable liquids, combustible dust, or easily ignit- able fibers. Hazardous location valves are recommended, or in some cases compulsory, where a high level of protection from explosion is required. For applications that require low power, a low watt version is also offered.

An increasingly popular option for general purpose or safety valves in pneumatic and hydraulic applications is valves with

a low wattage solenoid. The low power draw of these valves has increased their application to include hot air, other media, through the use of different seals.

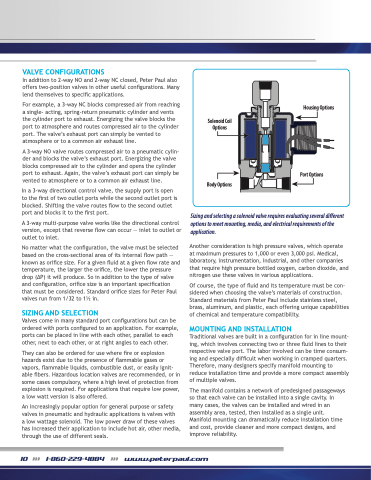

Solenoid Coil Options

Body Options

Housing Options

Port Options

Sizing and selecting a solenoid valve requires evaluating several different options to meet mounting, media, and electrical requirements of the application.

Another consideration is high pressure valves, which operate at maximum pressures to 1,000 or even 3,000 psi. Medical, laboratory, instrumentation, industrial, and other companies that require high pressure bottled oxygen, carbon dioxide, and nitrogen use these valves in various applications.

Of course, the type of fluid and its temperature must be con- sidered when choosing the valve’s materials of construction. Standard materials from Peter Paul include stainless steel, brass, aluminum, and plastic, each offering unique capabilities of chemical and temperature compatibility.

MOUNTING AND INSTALLATION

Traditional valves are built in a configuration for in line mount- ing, which involves connecting two or three fluid lines to their respective valve port. The labor involved can be time consum- ing and especially difficult when working in cramped quarters. Therefore, many designers specify manifold mounting to reduce installation time and provide a more compact assembly of multiple valves.

The manifold contains a network of predesigned passageways so that each valve can be installed into a single cavity. In many cases, the valves can be installed and wired in an assembly area, tested, then installed as a single unit. Manifold mounting can dramatically reduce installation time and cost, provide cleaner and more compact designs, and improve reliability.

10 >>> 1-860-229-4884 >>> www.peterpaul.com