Seal Material

Seal Material PeterPaul offers a large selection of optional seal materials. Standard seal material for catalog valves is nitrile elastomer, a good general purpose compound, satisfactory for most applications. Insert materials such as FKM, Nordel, KeL-F®, and Teflon® are available for applications where excessive heat is a factor, or for use with any media that can cause insert swelling or deterioration. Consult factory for proper usage.

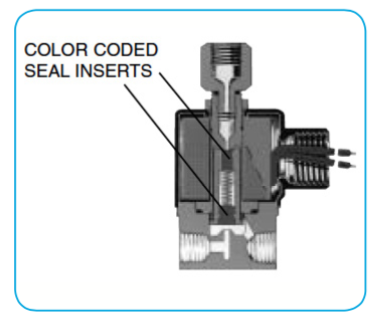

| TRADE NAME | COLOR CODE |

| HYPALON ® | Green |

| Neoprene ® | Red |

| Neoprene ® | Black |

| Nylon | Opaque |

| Teflon ® | White |

| Urethane ® | Yellow |

| FKM | Brown |

| Santoprene ® 2 | Off-White |

| KEL-F ® 1 | Opaque |

| Nitrile (Buna N) | Blue |

FKM Seals

For Gasoline And Propane Valve Applications

FKM solenoid valve seals are used for powered-vehicles and reformulated gasoline applications where solenoid valve seal swelling, cracking, and decomposition are occurring over time. This has created the need to reformulate existing FKM compounds to maximize their properties in reformulated gasolines with up to 15% MTBE and alcohol.

By maximizing the fluorine content of the FKM seals, swell is reduced. Further enhancement of the physical properties is made by removing the traditional colorant and adding carbon black. Beyond vehicular applications other related uses, particularly the medical field, have shown to be more stable and long-lasting when the FKM is applied.

EPDM Seals

High Pressure Gas Applications

Special EPDM (Ethylene Propylene Diene Monomers) seals are used where high-pressured gases tend to be absorbed in standard rubber seals. When gas is absorbed into a rubber solenoid valve seal it will cause the rubber to display a phenomenon called explosive decompression. If the system is vented or pressured reduce, gas that is trapped inside will cause the seal to balloon and swell, sometimes fracturing.

Used in place of conventional seal materials, such as urethanes, EPDM is more suitable for high pressured gases used in aerospace projects.

PERLAST ® SEALS

Affordable for Volume Valve Applications

Perlast ® Perfluorocarbon elastomer seals, a product of Precision Polymer Engineering Limited, are highly resistant to more than 1600 chemicals. They are practically inert to most chemically-induced swelling and last longer than other elastomer seals. With a useful temperature range of +20 °F to +500 °F, Perlast is versatile enough for use in many challenging environments. For higher or lower temperatures, please consult the factory.

Perlast ® is an expensive design material, even for medical and chemical resistant applications where no other seal material is durable enough. These molded seals often double the price of comparable valves incorporating other elastomer seals. This can be a “non-starter” for many applications and designs that are highly price sensitive.

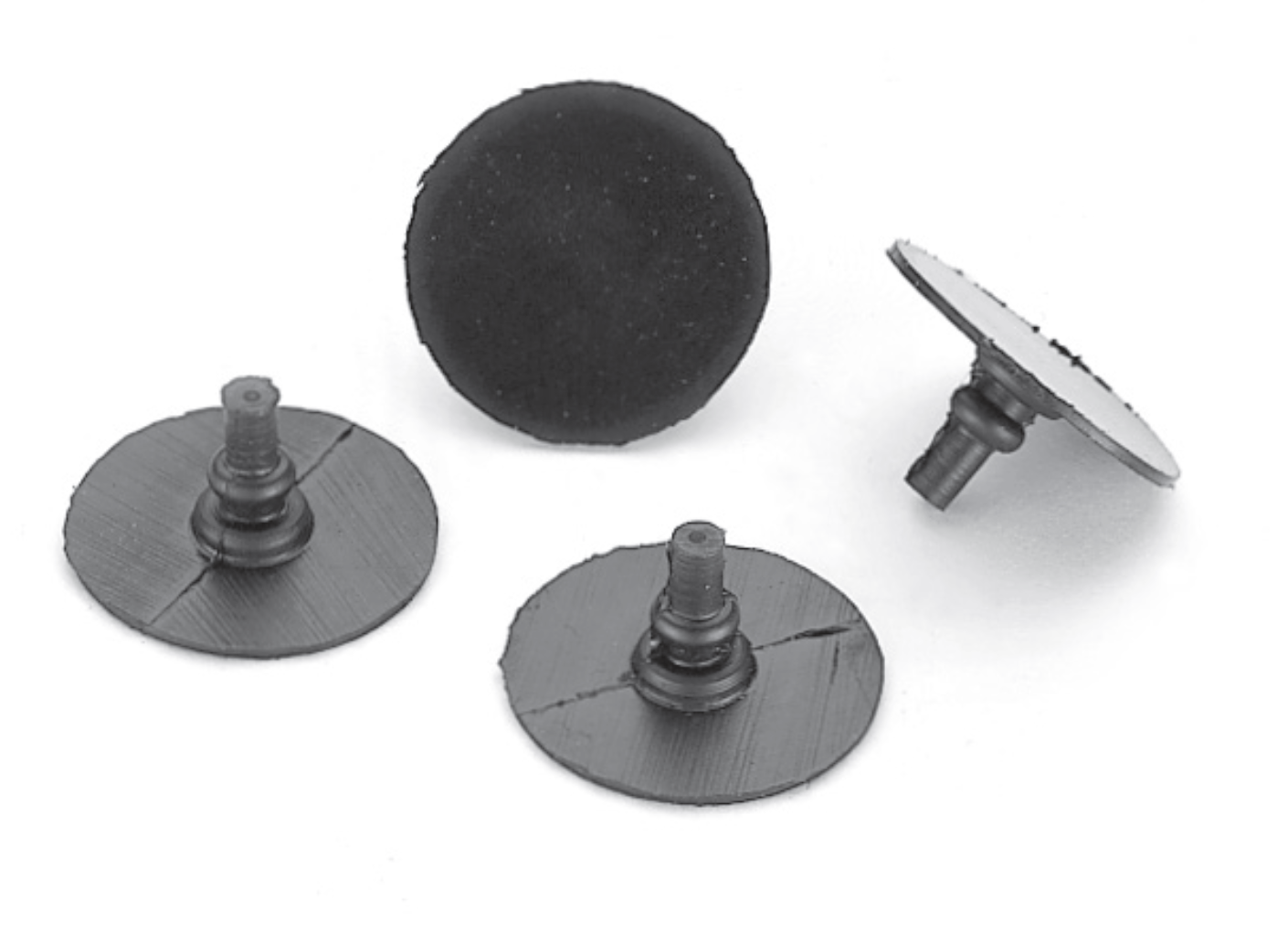

At PeterPaul, we’ve developed a significant cost saving procedure for laser-cutting Perlast® from sheet stock for use in our solenoid valve plunger assemblies. The amount of material used for each seal is reduced by half, thus reducing the cost per seal, even in small quantities, by as much as 40 to 60 percent. Previously molded seals, requiring more than double the amount of Perlast®, are replaced by a seal disc and stainless steel cup which are pressed together into a plunger blank. The seal cup controls the plunger length more efficiently and two notches on the seal circumference allow the seal to vent gases from within the plunger assembly.

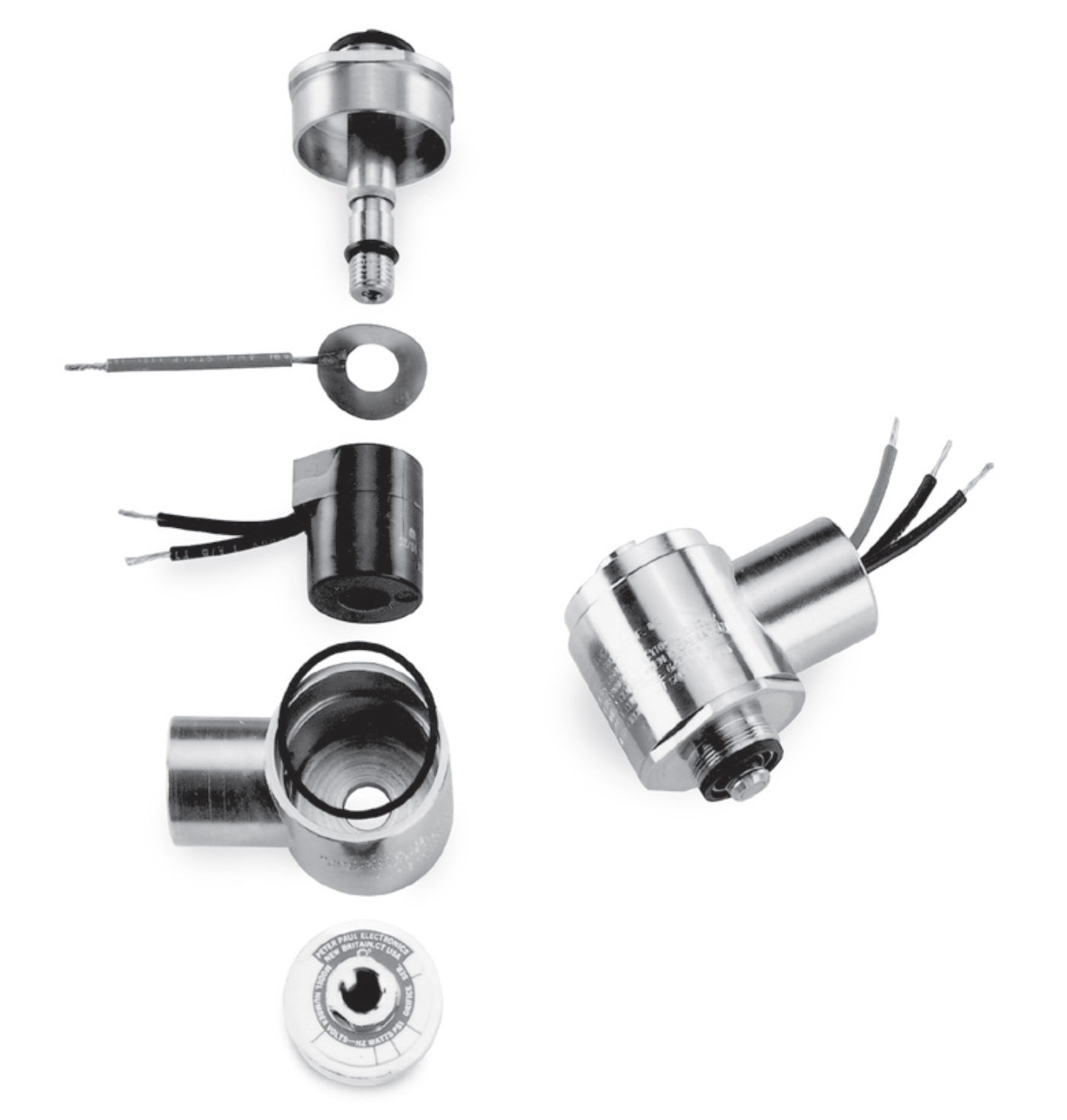

Added Moisture Protection Available for Series 50 Explosion-Proof Solenoid Valves

Extreme Weather Conditions

Our Series 50 explosion-proof solenoid valves and operators with molded coil for hazardous locations are offered with added protection from moisture in the form of O-rings and flat gasket fluorocarbon elasometer seals. These added seals will provide a solenoid valve at lower cost than one with a fully potted coil, top and bottom seal, and an RTV conduit seal.

Explosion-Proof Solenoid Valves are offered in several designs, based on maximum operating pressure differential, orifice size, CV factor, and operating media. These valves operate in hot water, steam, gasoline, oil, refrigerant, hydraulic fluid, and other environments requiring special seal materials. This design with 1/8” NPT allows these valves to meet the requirements hazardous locations, Class 1 Group C and D, and Class II Group E, F, and G.

Swell-Resistant Printers Gum Seals

We have an elastomer with customized nitrile rubber and unique for use of water-based printing inks. We are supplying this in conventional plungers and disk compensated plungers and media isolation diaphragms for ink dispensing and retrieval system, some in high-speed ink jet printers.

Normal elastomers and printer inks can sometimes combine and swell causing the lettering and logo to become distorted. This special elastomer molds well in existing tooling and is economical, performing well for the water-based inks. This product is available in Series 50 and 20 sizes in the diaphragm media isolation valves.

Solenoid Valves for Low Temperature Applications

Our solenoid valves are also widely employed at low temperatures to -40°C involving gaseous and liquid compounds including refrigerants and liquid nitrogen. For these uses, the full range of our 2-way and 3-way valves can be specified with the Teflon or Kel-F seals required for processing semi corrosives; typically all valves must be cleaned for oxygen service to remove oil and other surface contaminants. In many applications a compressed liquid is metered by the valve. Many of the valves will be UL recognized and CSA listed.

Food-Grade Valve Applications

Vending Machines

NSF 169 covers sanitation requirements for equipment and devices used in storing, preparing or handling foods and beverages. EPDM and Santoprene® are materials that meets the FDA requirements for nonmetallic material that comes in contact with food–type media. Fluorel® is used where higher temperatures exist.